Spacilization

M.TECH- ADVANCED MANUFACTURING TECHNOLOGY (PART TIME)

Duration

2 Years

(2 Sem/year)

Course Fees

INR 50000

semester

Eligibility

Above 45%

Exam Pattern

online

mic & camera

Learning

onlineLMS

LIVE & Record video

Admission

Open

dec / jul

Course Description M.TECH- ADVANCED MANUFACTURING TECHNOLOGY (PART TIME)

The Online M.Tech Advanced Manufacturing Technology program offers a specialized and flexible approach to obtaining a Master of Technology (M.Tech) degree with a focus on advanced manufacturing techniques and technologies. This program is designed for individuals who seek to enhance their knowledge and skills in the field of manufacturing while benefiting from the convenience of online learning.

The Online M.Tech Advanced Manufacturing Technology program is a comprehensive and flexible degree that provides students with a deep understanding of advanced manufacturing processes, technologies, and management principles. This program is structured to equip students with the necessary expertise to address the challenges and opportunities in modern manufacturing industries.

The curriculum of the Online M.Tech Advanced Manufacturing Technology program covers a wide range of topics, including additive manufacturing, computer-aided design and manufacturing, smart manufacturing, sustainable manufacturing, robotics, and automation. Students have the flexibility to tailor their studies to their specific interests and career goals within the field of advanced manufacturing.

Course Highlights

Why Choose Online M.Tech Advanced Manufacturing Technology:

There are several compelling reasons to consider the Online M.Tech Advanced Manufacturing Technology program:

1. Flexibility: The online format allows students to study at their own pace and from anywhere in the world, making it ideal for working professionals or individuals with other commitments.

2. Specialized Curriculum: The program offers a specialized curriculum focused on advanced manufacturing technologies and techniques, providing students with in-depth knowledge and skills that are highly relevant in today's manufacturing industry.

3. Industry-Relevant Skills: Students gain practical, hands-on experience with the latest tools, software, and technologies used in advanced manufacturing settings, preparing them for roles in research, development, and management.

4. Career Advancement: Graduates of the program are well-equipped to pursue career opportunities in various sectors of the manufacturing industry, including aerospace, automotive, electronics, healthcare, and more. The specialized skills and knowledge acquired through the program can lead to enhanced career prospects and higher earning potential.

5. Networking Opportunities: The online format provides opportunities for students to connect with industry professionals, researchers, and fellow students from around the world, facilitating valuable networking and collaboration opportunities.

Who Should Apply:

The Online M.Tech Advanced Manufacturing Technology program is suitable for a wide range of individuals interested in advancing their careers in manufacturing, including:

1. Engineering Professionals: Engineers with a background in mechanical engineering, manufacturing engineering, industrial engineering, or related fields can benefit from the specialized knowledge and skills offered by the program to advance their careers in advanced manufacturing.

2. Industry Practitioners: Professionals working in the manufacturing industry who wish to update their skills, stay current with industry trends, and enhance their career prospects can benefit from the program's flexible online format and industry-relevant curriculum.

3. Recent Graduates: Graduates with a bachelor's degree in engineering or a related field who are interested in pursuing a career in advanced manufacturing can gain a competitive edge by completing the Online M.Tech Advanced Manufacturing Technology program.

4. Career Changers: Individuals from diverse backgrounds who are looking to transition into a career in manufacturing can benefit from the program's specialized curriculum and flexible learning options.

When Should I Pursue an Online M.Tech Advanced Manufacturing Technology:

The Online M.Tech Advanced Manufacturing Technology program can be pursued at any stage of your academic or professional journey. Whether you are a recent graduate, a working professional in the manufacturing industry, or someone looking to transition into a career in manufacturing, the program offers the flexibility to accommodate your needs.

If you are a recent graduate with a bachelor's degree in engineering or a related field, pursuing the Online M.Tech Advanced Manufacturing Technology program can be a great way to gain specialized knowledge and skills that are highly valued in the manufacturing industry.

For working professionals in the manufacturing industry, the program offers the opportunity to enhance your qualifications, update your skills, and advance your career without interrupting your current job responsibilities.

For individuals looking to transition into a career in manufacturing, the program provides a comprehensive understanding of advanced manufacturing technologies and techniques, preparing you for roles in research, development, and management.

Key Highlights:

The Online M.Tech Advanced Manufacturing Technology program offers several key highlights that make it an attractive choice for individuals seeking to advance their careers in manufacturing:

1. Specialized Curriculum: The program offers a specialized curriculum focused on advanced manufacturing technologies and techniques, providing students with in-depth knowledge and skills that are highly relevant in today's manufacturing industry.

2. Flexibility: The online format allows students to study at their own pace and from anywhere in the world, making it ideal for working professionals or individuals with other commitments.

3. Industry-Relevant Skills: Students gain practical, hands-on experience with the latest tools, software, and technologies used in advanced manufacturing settings, preparing them for roles in research, development, and management.

4. Career Advancement: Graduates of the program are well-equipped to pursue career opportunities in various sectors of the manufacturing industry, including aerospace, automotive, electronics, healthcare, and more. The specialized skills and knowledge acquired through the program can lead to enhanced career prospects and higher earning potential.

5. Networking Opportunities: The online format provides opportunities for students to connect with industry professionals, researchers, and fellow students from around the world, facilitating valuable networking and collaboration opportunities.

Course Duration:

The duration of the Online M.Tech Advanced Manufacturing Technology program may vary depending on the institution and the mode of study (full-time or part-time). However, on average, the program can be completed in two to three years of full-time study or longer if pursued on a part-time basis.

The Online M.Tech Advanced Manufacturing Technology program is designed to provide flexibility to students, allowing them to study at their own pace. Some institutions may offer accelerated options or allow students to take breaks between courses if needed. The duration of the program may also depend on the number of courses taken per semester and the student's ability to complete the required credits.

It is important to consider personal commitments and time availability when planning to pursue the Online M.Tech Advanced Manufacturing Technology program. Students should consult with the institution offering the program to get a clear understanding of the course duration and any options for flexible study arrangements.

Academic Fees:

The academic fees for the Online M.Tech Advanced Manufacturing Technology program may vary depending on the institution offering the program and the mode of study (full-time or part-time). It is recommended to check with the specific institution for the most accurate and up-to-date information on fees.

The fees for the Online M.Tech Advanced Manufacturing Technology program typically include tuition fees, registration fees, and any additional charges for study materials or online learning platforms. Some institutions may offer financial aid or scholarships to eligible students pursuing advanced degrees in engineering. It is advisable to explore these options and inquire about any available funding opportunities.

When considering the academic fees for the program, it is important to also factor in other costs such as textbooks, technology requirements, and any additional expenses related to online learning, such as internet access or software requirements. Planning and budgeting for these costs can help ensure a smooth and successful academic journey.

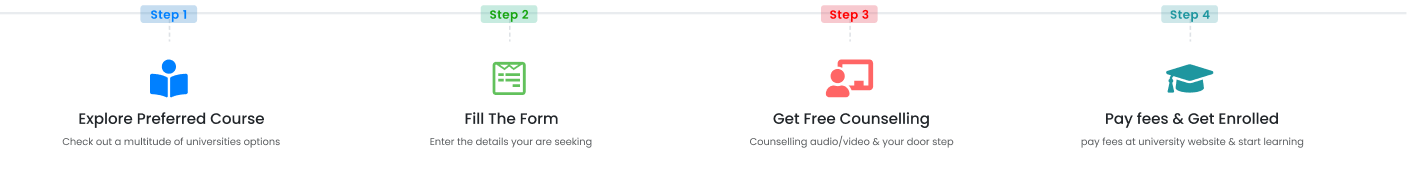

Admission Procedure:

The admission procedure for the Online M.Tech Advanced Manufacturing Technology program may vary depending on the institution offering the program. However, some common steps involved in the admission process include:

1. Research and Choose Institutions: Start by researching institutions that offer the Online M.Tech Advanced Manufacturing Technology program. Consider factors such as accreditation, curriculum, faculty, and student support services specific to advanced manufacturing technology.

2. Check Admission Requirements: Review the admission requirements of the institutions you are interested in. These may include educational qualifications, work experience, language proficiency, and any additional documents or tests required for the program.

3. Complete the Online Application: Once you have chosen an institution, complete the online application form for the Online M.Tech Advanced Manufacturing Technology program. Provide accurate and up-to-date information, and ensure that all required documents are submitted.

4. Pay Application Fee: Some institutions may require an application fee to process your application. Pay the fee as per the instructions provided by the institution.

5. Submit Supporting Documents: Submit all the required supporting documents, such as transcripts, letters of recommendation, statement of purpose, and any other documents specified by the institution.

6. Technical Requirements: Since the program is delivered online, applicants must ensure they meet the technical requirements specified by the institution.

7. Await Admission Decision: After submitting your application and supporting documents, wait for the admission decision. This may take some time, so it is advisable to apply well in advance of the program start date.

8. Accept Offer and Enroll: If you receive an offer of admission, carefully review the offer and any conditions attached. Accept the offer as per the instructions provided by the institution and complete the enrollment process.

It is important to note that the admission procedure may vary, and it is recommended to refer to the specific institution's website or contact their admissions office for detailed and accurate information.

Why Opt for Education Loan:

Considering an M.Tech in Advanced Manufacturing Technology requires substantial investment, opting for an education loan can provide a viable financial solution. Here's why you may find an education loan beneficial for financing your advanced degree:

1. Financial Assistance: Pursuing an M.Tech in Advanced Manufacturing Technology involves expenses like tuition fees, research materials, and specialized equipment. Education loans offer financial assistance tailored to cover these costs, easing the financial burden associated with advanced studies in manufacturing technology.

2. Flexible Repayment Options: Education loans typically come with flexible repayment plans, allowing you to repay the loan after completing your studies or in installments over a designated period. This flexibility ensures that you can manage your finances effectively while focusing on your advanced manufacturing coursework.

3. Build Credit History: Responsibly managing an education loan and timely repayments can help you build a positive credit history. This can be advantageous for future financial endeavors, including securing loans for entrepreneurial ventures or investment in advanced technology projects.

4. Focus on Studies: By availing an education loan, you can concentrate on your M.Tech studies without the immediate financial stress. This enables you to dedicate yourself fully to mastering advanced manufacturing concepts, research, and practical applications.

5. Support Career Goals: An M.Tech in Advanced Manufacturing Technology can significantly enhance your career prospects in various sectors, including aerospace, automotive, and electronics industries. An education loan ensures you have the necessary financial support to invest in your education and pursue opportunities aligned with your career goals.

It's imperative to carefully assess the terms and conditions of the education loan, including interest rates and repayment terms, to make an informed decision regarding financing your M.Tech in Advanced Manufacturing Technology.

Is M.Tech in Advanced Manufacturing Technology Worth It?

Determining the value of an M.Tech in Advanced Manufacturing Technology depends on individual aspirations and professional objectives. Here are some factors to consider when evaluating the worth of pursuing this specialization:

1. Career Advancement: An M.Tech in Advanced Manufacturing Technology equips you with specialized knowledge and skills highly sought after in industries embracing advanced manufacturing processes. It can significantly enhance your career advancement opportunities, particularly in roles involving research, development, and implementation of cutting-edge manufacturing technologies.

2. Specialized Expertise: Pursuing an M.Tech in Advanced Manufacturing Technology allows you to delve deeply into areas like additive manufacturing, automation, robotics, and digital manufacturing. This specialized expertise can differentiate you in the job market and position you for leadership roles in industries at the forefront of technological innovation.

3. Industry Relevance: The demand for professionals with expertise in advanced manufacturing technologies continues to grow across sectors such as aerospace, automotive, medical devices, and consumer electronics. An M.Tech in this specialization ensures your skills remain relevant and in-demand in today's rapidly evolving manufacturing landscape.

4. Research Opportunities: Advanced manufacturing technology is a field ripe with research opportunities, ranging from developing novel manufacturing processes to optimizing existing systems for efficiency and sustainability. Pursuing an M.Tech offers you the chance to contribute to cutting-edge research projects and make significant advancements in the field.

5. Global Opportunities: The skills acquired through an M.Tech in Advanced Manufacturing Technology are transferable across borders, opening up opportunities for international career growth and collaboration with global manufacturing firms and research institutions.

Ultimately, the value of an M.Tech in Advanced Manufacturing Technology lies in its potential to align with your career aspirations, facilitate professional growth, and contribute to advancements in the manufacturing industry.

Examination Pattern for M.Tech in Advanced Manufacturing Technology:

Online examinations for M.Tech in Advanced Manufacturing Technology are typically conducted through secure platforms to ensure integrity and fairness. Here's an overview of the examination pattern:

1. Exam Formats: Exams may include multiple-choice questions, practical assessments, case studies, and research-based assignments, reflecting the diverse nature of advanced manufacturing coursework.

2. Exam Scheduling: The exam schedule is determined by the university or institution, with students informed about the date, time, and duration of each exam in advance.

3. Accessing the Exam: Students access exams through designated online platforms using their credentials. It's essential to have a stable internet connection and compatible devices for seamless exam participation.

4. Exam Duration: Exams typically have predetermined durations during which students must complete and submit their responses. The duration varies based on the complexity of the exam and the number of questions.

5. Submission Process: Students submit their exam responses through the online platform within the specified time frame. The platform may include features like timers and submission buttons to guide students through the process.

6. Monitoring and Proctoring: To maintain academic integrity, online exams may incorporate remote proctoring or monitoring mechanisms, such as webcam surveillance and AI algorithms, to deter cheating attempts.

7. Grading and Feedback: After submission, exams are graded by instructors or examiners according to established criteria. Students receive grades and feedback through the online platform or institutional communication channels.

It's essential for students to familiarize themselves with exam guidelines, technical requirements, and academic integrity policies to ensure a smooth examination experience and successful outcomes in their M.Tech studies.

Course Curriculum

| Semester | Subjects |

| 1 | Advanced Engineering Mathematics, Materials Science and Engineering, Manufacturing Processes and Techniques, Research Methodology |

| 2 | Computer-Aided Design and Manufacturing, Advanced Manufacturing Technologies, Quality Control and Assurance, Research Proposal Development |

| 3 | Advanced Machining Processes, Additive Manufacturing, Robotics and Automation in Manufacturing, Comprehensive Exam Preparation |

| 4 | Industrial Engineering and Management, Advanced Topics in Manufacturing Technology, Dissertation Writing, Dissertation Defense and Viva Voce |

Duration of Specialization

2 Years

Eligibility Criteria

Requirements:

To enroll in the Online M.Tech Advanced Manufacturing Technology program, applicants must meet certain requirements. These requirements may vary depending on the institution offering the program. However, some common requirements include:

1. Bachelor's Degree: Applicants must have a bachelor's degree in engineering or a related field from a recognized institution.

2. Work Experience: Some institutions may require applicants to have relevant work experience in the manufacturing industry, although this may not be mandatory for all programs.

3. Language Proficiency: Since the program is conducted in English, applicants may be required to demonstrate proficiency in the English language through standardized tests .

4. Application Process: Applicants are typically required to complete an online application form and submit supporting documents, such as transcripts, letters of recommendation, and a statement of purpose outlining their interest in advanced manufacturing technology.

5. Technical Requirements: Since the program is delivered online, applicants must have access to a reliable internet connection and a computer or device capable of running the required software for engineering-related coursework.

It is important to note that specific requirements may vary, and it is recommended to check the admission criteria of the institution offering the Online M.Tech Advanced Manufacturing Technology program.

Skills Required:

The Online M.Tech Advanced Manufacturing Technology program equips students with a range of skills that are essential for success in the field of advanced manufacturing. Some of the key skills developed through the program include:

1. Advanced Manufacturing Techniques: Students gain expertise in advanced manufacturing techniques such as additive manufacturing, computer-aided design and manufacturing, robotics, and automation.

2. Problem-Solving: The program enhances students' problem-solving abilities, enabling them to address complex challenges in advanced manufacturing settings.

3. Project Management: Students learn project management skills essential for planning, executing, and monitoring manufacturing projects effectively.

4. Critical Thinking: The program fosters critical thinking skills, allowing students to analyze manufacturing processes, identify areas for improvement, and propose innovative solutions.

5. Communication: Students develop strong communication skills, enabling them to effectively convey technical information and collaborate with colleagues in multidisciplinary teams.

6. Leadership: The program cultivates leadership skills necessary for managing manufacturing teams and driving continuous improvement initiatives.

7. Technology Integration: Students learn to integrate emerging technologies into manufacturing processes to enhance productivity, quality, and efficiency.

8. Sustainable Manufacturing Practices: The program emphasizes sustainable manufacturing practices, equipping students with the knowledge and skills to minimize environmental impact and optimize resource utilization.

admission procedure

Job Opportunities

Job Opportunities in Advanced Manufacturing Technology:

An M.Tech in Advanced Manufacturing Technology unlocks a wide array of job opportunities across various sectors at the forefront of technological innovation. Here are some potential career paths for graduates in this specialization:

1. Research and Development Engineer: Graduates can pursue roles in research and development, where they contribute to the design, optimization, and implementation of advanced manufacturing processes and technologies.

2. Automation Engineer: With expertise in automation and robotics, graduates can work in roles focused on designing, programming, and deploying automated manufacturing systems to improve efficiency and productivity.

3. Additive Manufacturing Specialist: As additive manufacturing continues to revolutionize production processes, specialists in this area are in high demand. Graduates can work with companies utilizing additive manufacturing technologies such as 3D printing for prototyping, customization, and production.

4. Supply Chain and Logistics Manager: Advanced manufacturing technologies impact supply chain and logistics operations significantly. Graduates can leverage their expertise to optimize supply chain processes, manage inventory, and streamline logistics operations for manufacturing firms.

5. Quality Assurance Manager: Ensuring product quality and compliance with industry standards is crucial in advanced manufacturing. Graduates can pursue roles in quality assurance, where they develop and implement quality control processes and standards to maintain product integrity.

6. Industry Consultant: Experienced M.Tech graduates may opt for consultancy roles, offering expertise and strategic guidance to manufacturing firms seeking to adopt advanced technologies, improve operational efficiency, and stay competitive in the market.

The job opportunities for M.Tech graduates in Advanced Manufacturing Technology are diverse and dynamic, offering avenues for specialization and career growth in a rapidly evolving industry landscape.

Top Recruiters

Top Recruiters in Advanced Manufacturing Technology:

Graduates with an M.Tech in Advanced Manufacturing Technology are highly sought after by leading organizations at the forefront of technological innovation. Here are some top recruiters in this field:

1. Tech Giants: Companies like Siemens, GE, and Bosch are actively investing in advanced manufacturing technologies and often recruit M.Tech graduates for roles in research, development, and engineering.

2. Automotive Industry: Leading automotive manufacturers such as BMW, Toyota, and Tesla seek M.Tech graduates with expertise in advanced manufacturing for roles in production engineering, process optimization, and automation.

3. Aerospace and Defense: Aerospace and defense firms like Boeing, Airbus, and Lockheed Martin require skilled professionals to drive innovation in manufacturing processes, materials, and technologies for aircraft and defense systems.

4. Medical Device Companies: With the growing demand for advanced medical devices, companies like Medtronic, Johnson & Johnson, and GE Healthcare recruit M.Tech graduates to develop and manufacture cutting-edge medical technologies.

5. Consulting Firms: Management consulting firms like McKinsey, BCG, and Deloitte engage M.Tech graduates as subject matter experts to advise clients on strategic initiatives related to advanced manufacturing and technology adoption.

6. Startups and Innovation Hubs: Emerging startups and innovation hubs focused on advanced manufacturing technologies offer exciting opportunities for M.Tech graduates to contribute to groundbreaking projects and entrepreneurial ventures.

Engaging in networking activities, internships, and research collaborations can enhance your visibility and attractiveness to potential employers in the advanced manufacturing sector.