Spacilization

B.TECH TOOL AND DIE MAKING

Duration

4 Years

(2 Sem/year)

Course Fees

INR 30000

semester

Eligibility

Above 45%

Exam Pattern

online

mic & camera

Learning

onlineLMS

LIVE & Record video

Admission

Open

dec / jul

Course Description B.TECH TOOL AND DIE MAKING

Being a specialized undergraduate program specialized for students interested in gaining a strong foundation in precision engineering and manufacturing technology, the B.Tech in Tool and Die Making Engineering program is concerned with the design, development, and production of tools, dies, molds, and precision components that find usage in industries encompassing automotive, aerospace, and consumer electronics.

Through more intensive hands-on didactic methods, model programs provide both critical theoretical inputs and essential hands-on skills in the important areas of tool design, manufacturing processes, and automation, assuring an advanced understanding of computer-aided design (CAD), computer-aided manufacturing (CAM), CNC programming, and Quality Control, among others. This puts graduates of this program in a choice position for a variety of careers in an ever-changing and growing manufacturing sector.

The syllabus of the B.Tech in Tool and Die Making Engineering is broad and flexible and deals with key subjects including tool design principles, die and mold manufacturing, materials science, metrology, and automation. Students also learn about CNC machine operation, CAD-CAM software, and quality management systems. The program aims to bestow on the students the required technical knowledge and skills for a successful career in tool room operations, production planning, and design innovation, thereby fitting them to meet the skill gap in the global manufacturing sector

Course Highlights

Why Choose B.Tech in Tool and Die Making Engineering (Online/Hybrid Mode)?

The B.Tech in Tool and Die Making Engineering is aimed at imparting the students with advanced technical knowledge and some practical skills for pursuing a career in precision manufacturing, design of products, and mold/tool development. The course, available in online or hybrid mode, is meant for the aspirants who have a passion for mechanical design and tooling technologies.

Industry-Relevant Curriculum: The course covers relevant subjects in the field of mold and die design, CNC programming, CAD/CAM, material science, manufacturing processes, and quality control. The syllabus is updated regularly to maintain the demand of the manufacturing and automobile industries.

Flexible Learning Model: Online and hybrid options allow students to handle studies along with other work or personal commitments. This is an ideal choice for diploma holders, working personnel, and engineering students living in very remote areas.

Practical Training: Though online/hybrid, the program integrates practical labs and simulations along with optional long-term on-site industrial training in collaboration with certified manufacturing units.

Career-Ready Outcomes: The graduates will be equipped to enhance their employability in automobile, aerospace, defense manufacturing, precision engineering, and tooling industries. Tool designers, CNC Programmers, die/mold engineers, and quality inspectors could all find a place.

Expert Guidance: Student recruitment will be guided by faculty and industry professionals with decades of industry experience, giving real-life perspectives. The mentorship thus provided will help align students with globally accepted manufacturing standards.

Who Should Apply?

The B.Tech. in Tool and Die Making Engineering program turns out to be an ideal course for:

Mechanical/Production Engineering Diploma Holders: Candidates who aspire to have advanced knowledge and specialization in fields like tool engineering and CAD/CAM technologies.

Employment Professionals with Manufacturing Units: Those working in tool rooms, die shop and CNC based industries who desire to develop skills further for transitioning possibely towards different higher technical or managerial roles.

Technical Apprentices and ITI Graduates: Those with some hands-on exposure on machine tools or fabrication, who want to do a full engineering degree for better job scope.

Career Change: People willing to shift to high-demand technical roles in designing, production, or quality assurance in the domain of manufacturing.

When Should You Pursue B.Tech in Tool and Die Making Engineering?

The program can be pursued at any stage of one's academic or professional career-whether one is a diploma holder just out of a polytechnic institution, an experienced machinist, or an aspirant with a non-engineering background but technical experience.

For experienced practitioners, the course provides flexibility between continuing their professional work while pursuing further technical qualifications. For students, a solid foundation is laid in tool design and manufacturing processes for precision engineering careers.

Key Highlights:

- Specialized Curriculum for tooling design, mould making, die casting, CNC operations, CAD-CAM-CAE, and industrial automation.

- Hybrid and online learning modes for students worldwide working across geographies and time zones.

- Projects and simulation exercises that are current with industry practices in the manufacturing sector.

- Faculty with tool room and industry experience imparting practical exposure and job readiness.

- Career pathways into automotive, aerospace, electronics manufacturing, defence, etc.

Why Opt for Education Loan for B.Tech in Tool and Die Making Engineering?

- Tuition Fee Plus Industrial Training: The education loans cover tuition fees, lab sessions, training visits, and licenses for software used in connection with the course.

- Financial Stress Relief: Instead of choosing between studying and repayment, students will have the opportunity to take a moratorium period and have flexible EMIs before they start having to think about working.

- Constructs Credit History: A timely repayment of education loans helps students build their strong credit profiles early in their careers.

- Improves Career Prospects for Growth: Getting a B.Tech in this domain can significantly increase employability and salary potential in industrial areas as well as SEZs.

Is B.Tech in Tool and Die Making Worth It?

Absolutely. Here’s why:

- Precision manufacturing has been the most-enticing industry for automating and exporting.

- India is emerging from non-mold making to becoming a worldwide home for die/mold production and high-precision tooling.

- This discipline not only introduces one to work opportunities but also pathways towards entrepreneurship- setting up a tool room or establishing a CNC machining unit.

- The extremely highly specialized and practical skills learned through training would be in demand in the industries of automobile, defense, white goods manufacture, and aerospace.

Examination Pattern:

- The semester exams are veering towards offline modes now, or in-person, where applicable. These tests, of course, are the mixed bag of theory and practical subjects.

- Practical Evaluation: Wherein simulation exercises, CAD/CAM assignments, CNC programming exercises, and tool design projects are carried out.

- Internship/Industry evaluation: That is, during the final semester, an assessment of internship performance and project viva is presented.

- Continuous evaluation: Weekly quizzes, assignments, and case studies for internal evaluations.

- Discipline Semester Evaluation: Some examinations are conducted offline or physically, depending on the required format, and are a mix of theory and practical courses.

- Practical Evaluations: Involving various simulations, CAD and CAM assignments, CNC programming exercises, and tool design projects.

- Internship/Industry Evaluation: In the last semester, one part considers the performance in the internship plus a viva on the project.

- Continuous Evaluation: Weekly quizzes, assignments, and case studies as part of internal assessment.

Course Curriculum

The certification levels will lead to Diploma/Advanced Diploma/B. Voc/B.Tech.

B.Voc at Industrial Centres and B.tech will be offered at the University.

| Award | Duration | NSQF level | NCRF level |

| Voc.Diploma | 1 Year | 5 | 4.5 |

| Voc.Advance Diploma | 2 Year | 6 | 5.0 |

| B.Voc.Degree | 3 Year | 7 | 5.5 |

| B.Tech | 4 Year | NA | 6 |

Duration of Specialization

4 Years

Eligibility Criteria

Fresh Entry (10+2 PCM): 4 Years (8 Semesters)

Lateral Entry (Diploma Holders): 3 Years (6 Semesters)

Flexible Duration: For part-time or modular learners, duration may vary per credit structure

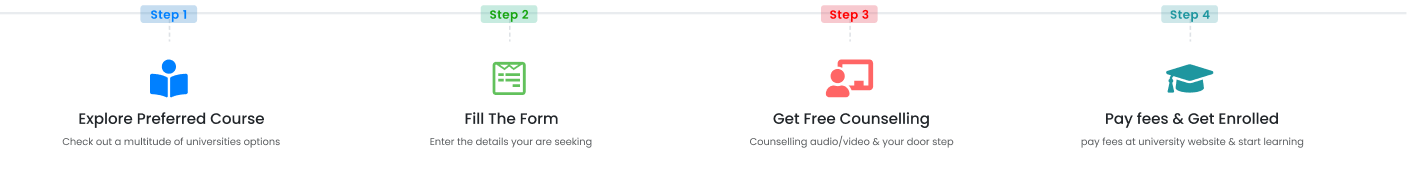

admission procedure

Job Opportunities

Specialization in a highly technical field like Tool and Die Making opens doors to careers in precision engineering, industrial design, and manufacturing. This curriculum prepares students with practical skills in tool design, mold engineering, CAD/CAM/CAE applications, CNC programming, and materials technology, making them the most sought-after within high-performance manufacturing systems.

Perhaps job openings for BTech Tool and Die Making graduates include:

Tool Design Engineer: Responsible for the designing of precision tools, jigs, and fixtures using CAD/CAM software for industries including but not limited to automotive, aerospace, and consumer electronics.

Mold and Die Engineer: Responsible for the design and maintenance of injection molds, press tools, and die-casting components for mass production.

CNC Programmer/Machining Specialist: Writes and optimizes CNC code for high precision machining, ensuring that quality, speed, and accuracy are maintained on shop floors.

Manufacturing Engineer: Responsible for improving production process, selecting appropriate tooling, and ensuring quality standards are met during all processes involved in manufacturing.

Quality Control & Assurance Engineer: Responsible for testing and inspection of manufactured tools, dies, and components to ascertain compliance with engineering specifications.

Production Planner: Monitors tool room activities and provides coordination between design and timely manufacture and maintenance of dies and molds.

Research & Development Associate: In his/her capacity, he/she will be involved in innovations in materials, die technologies, and manufacturing systems in the R&D units of engineering firms.

Entrepreneur/Tool Room Owner: Graduates with an enterprising spirit may set up precision tool manufacturing units, CNC job shops, or appoint themselves to supply custom die requirements for nearby industries.

Job opportunities can vary based on previous experience, industry sector, and other qualifications obtained. Intern involvement, industrial exposure, and continuity of upskilling in advanced design tools and manufacturing technologies all add value to employability into this niche-filled domain.

Top Recruiters

The graduates from B.Tech in Tool and Die Making are jewels in the eyes of the precision industries which require technical excellence, transforming manufacturing, and the much-needed know-how in tooling systems. Available from automotive, aerospace, heavy engineering, electronics, and consumer goods, all of them have important career opportunities for professionals whose specialty is here.

Some of the Top Companies Recruiting Graduates from B.Tech Tool and Die Making

Tool & Die Manufacturing Companies

Such companies include those involved in die casting and press tools to mold making, as well as jigs and fixtures. Such companies depend heavily on very skilled professionals.

Godrej Tooling

Indo MIM

Tungaloy India

Jamna Auto Industries

Lakshmi Machine Works (LMW)

Automobile and Auto Component Manufacturers

Hence, such companies employ tool engineers for mass production of very intricate components.

Tata Motors

Maruti Suzuki

Mahindra & Mahindra

Bosch Ltd.

Sundaram Clayton

Hero MotoCorp/ TVS/ Bajaj Auto

Precision Engineering & Aerospace

High-tech companies will require tooling and mould development of ultra-precise types for specialized parts.

HAL (Hindustan Aeronautics Ltd.)

ISRO Tool Room Divisions

Bharat Forge

GE Aviation India

CAD/CAM/CAE and Engineering Design Companies

Design and simulation-based companies recruit engineering professionals in tool design with a strong background in 3D modeling and simulation.

Siemens PLM

Dassault Systèmes

Tata Technologies

Capgemini Engineering

Consumer Electronics and Plastic Mold Industries

Molding engineers are involved in die cast and plastic injection tool development.

Videocon

Havells

Whirlpool

Panasonic India

Public Sector Undertakings and Government Tool Rooms

Tool and Die graduates have national tool design and training institutes as opportunities.

Central Tool Room & Training Centre Jain

MSME Tool Rooms

BHEL

DRDO

Internships, workshops, and certifications in areas such as advanced CAD/CAM, CNC simulation, GD&T, Lean Manufacturing, etc., are encouraged for ready industrial entry and being competitive in this specialized field for B. Tech Tool and Die Making graduates.