Spacilization

B.TECH IN MECHATRONICS AND INDUSTRIAL INSTRUMENTATION ENGINEERING

Duration

4 Years

(2 Sem/year)

Course Fees

INR 30000

semester

Eligibility

Above 45%

Exam Pattern

online

mic & camera

Learning

onlineLMS

LIVE & Record video

Admission

Open

dec / jul

Course Description B.TECH IN MECHATRONICS AND INDUSTRIAL INSTRUMENTATION ENGINEERING

These collaborators obtain advanced training without interrupting their work. This unique program combines academic brilliance with industrial exposure allowing professionals to balance their work commitments against their higher education seamlessly.

The program encompasses online theory sessions, weekend lab sessions, and practical modules in an innovative flexible module structure, making it easy to follow from anywhere and adaptable to individual schedules.

Course Highlights

Why Choose B.Tech in Mechatronics and Industrial Instrumentation Engineering under IPWP?

The B.Tech Mechatronics and Industrial Instrumentation Engineering-IPWP is a strategically designed work-integrated engineering program, which is being pursued by professionals in fields of automation, robotics, maintenance, or industrial systems. Built to merge employment with academic advancement, this program enables learners to gain a prestigious engineering degree while continuing their job, offering the perfect balance of theory, application, and flexibility.

Interdisciplinary and Work-Aligned Curriculum

This program covers an evolving blend of mechanical systems, electronics, control systems, sensors, PLC/SCADA, robotics, and industrial automation. Every module is fine-tuned to the real-world demands of industries such as automotive, process control, smart manufacturing, defense, and heavy engineering.

Flexible & Modular Learning for Professionals

The course is offered in a hybrid manner so that it does not unduly hamper the student's work-life. The course consists of online interactive classes, followed by weekend lab sessions and optional industrial workshops for additional extra time along with the self-paced modules which are suited for all the working professionals across the country.

Recognition of Prior Learning (RPL) under NCrF

Diploma or ITI holders, or those with relevant hands-on experience in automation, maintenance, or instrumentation, can even avail of academic credit through RPL, thus shortening their path to a full-fledged engineering degree on the National Credit Framework under NCrF.

Industry-Integrated Practical Learning

The theoretical coursework is complemented with numerous hands-on projects based on robotics simulation, sensor-based control systems, PLC programming, IoT-based monitoring, and industrial instrumentation systems. These projects can be developed in the workplace under the supervision of academic mentors and industry supervisors.

Career Advancement & Specialization

Graduates gain strong eligibility for roles in:

Automation and Control Systems

Maintenance and Plant Engineering

Robotics Integration

Process Instrumentation and Monitoring

Smart Manufacturing

Industrial R&D and Design

This program is thus a gateway to managerial positions, technical government jobs, and entrepreneurial opportunities in either automation, systems integration, or smart factory solutions.

The courses are delivered by experts in mechatronics, embedded systems, robotics, and instrumentation engineering, including professors and professionals from manufacturing, utilities, and automation. Students also benefit from one-on-one mentorship for personalized academic guidance and career planning.

Who Should Enroll?

Are diploma holders in Mechatronics, Mechanical, Electrical, or Instrumentation Engineering?

Working professionals in industrial automation, robotics, or control systems?

ITI graduates aiming to step up into engineering-level roles?

Plant maintenance engineers or shift supervisors seeking formal B.Tech qualifications?

Technicians and operators taking a step forward into design or control engineering?

When to Start?

Learners may enter this program at any point along the continuum-from fresh graduates to mid-career professionals working on industrial systems. The IPWP model allows for rolling admission and self-paced progression, making it the ideal choice for busy professionals.

Key Program Features

Specialized Focus: Robotics, Sensors, PLC/SCADA, Embedded Systems, and Industrial Automation

Hybrid Learning Model: Online classes + Weekend labs + Industrial modules

Real-Industry Projects: Execute projects at your workplace or partnered labs

Mentorship by Expert: Academicians and Industry Engineers with practical field experience

Strong Industry Alignment: Relevant across Smart Manufacturing, Utilities, Automotive, etc.

Academic Fee

Per Semester Fee: ₹25,000 – ₹75,000 (depending upon the university or delivery partner).

Add-ons: Robotics kits, PLC simulation software, virtual labs, instrumentation equipment.

Financial Aid: EMI plan, reimbursement from industries, upskilling grants, and educational loans.

Assessment & Evaluation

Examinations: Hybrid mode-wrtten & practical through simulation or hands-on labs.

Continuous Assessment: Weekly assignments, design of control systems, and circuit simulation-related challenges.

Major Project: Automation or instrumentation project based on an industry situation with a viva.

Course Curriculum

The certification levels will lead to Diploma/Advanced Diploma/B. Voc/B.Tech.

B.Voc at Industrial Centres and B.tech will be offered at the University.

| Award | Duration | NSQF level | NCRF level |

| Voc.Diploma | 1 Year | 5 | 4.5 |

| Voc.Advance Diploma | 2 Year | 6 | 5.0 |

| B.Voc.Degree | 3 Year | 7 | 5.5 |

| B.Tech | 4 Year | NA | 6 |

Duration of Specialization

4 Years

Eligibility Criteria

Fresh Entry (10+2 PCM): 4 Years (8 Semesters)

Lateral Entry (Diploma Holders): 3 Years (6 Semesters)

Flexible Duration: For part-time or modular learners, duration may vary per credit structure

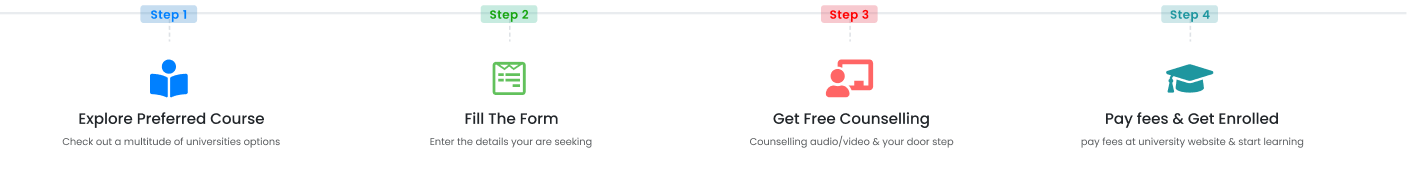

admission procedure

Job Opportunities

A B tech in mechatronics and industrial instrumentation engineering opens up myriad career pathways in engineering and across several automation-based industries. The multidisciplinary nature of this course integrates mechanical, electronics, control systems, computer science, and instrumentation engineering, equipping the graduates with the necessary skills to work in intelligent systems, automation, and smart manufacturing.

Some Job Profiles associated to the Online/Regular B.tech-Mechatronics & Instrumentation:

Automation Engineer:

This involves putting finals on automation systems in manufacturing industries and robotics-based environments using PLC, SCADA, and industrial robots.

Instrumentation Engineer:

The work includes sensors, measurement devices, and control systems monitoring and controlling physical quantities in industries like oil & gas, pharmaceuticals, food processing, and chemical manufacturing.

Robotics Engineer:

The Mechatronics graduate will design, construct, and program robots for assembly line operations, develop autonomous induced vehicles, or service robots for military and health operations.

Embedded Systems Engineer-hardware-software integrated systems are designed incorporating both software and hardware used specially in smart devices/appliances or industrial controllers, specifically focusing on automotive and electronics industries.

Maintenance & Reliability Engineer-These are employed for condition monitoring of electromechanical systems such as machinery health and implementation of predictive maintenance practices as personal experience would suggest.

Industrial IoT (IIoT) Specialist:

Graduates connect machines and analyze real-time data through IIoT technologies for the betterment of smart factories.

Design Engineer:

Innovative mechanical and electronic components or smart systems are designed with the help of CAD/CAM and simulation software.

Control Systems Engineer:

They design and manage advanced control systems involving process automation using feedback, loop, signal processing, and tuning.

Top Recruiters

Sure, one of the prime employers coming for recruitment for a wise range of breadth for engineering such as mechatronics, industrial instrumentation engineering graduates, and other applicable engineering systems uses mechanics, electronics, automation, and data-driven technologies in making of industries hybridized. Industryyard-run by such colleges are really considered much due to diverse interdisciplinary skills possessed by the respective graduates in both problem-solving.

Here are a few leading recruiters in full swing recruitment:

Automation & Robotics Companies:

Such companies tend to also look for recruitment for the detailed jobs for candidates in the field of PLC programming, robotic design, industrial-based automation, and intelligent system integration.

Smart Manufacturing & Industry 4.0 Enterprises:

Such organizations look for engineers working on IIoT, cyber-physical systems, and predictive maintenance- all required for manufacturing industries transforming digitally.

Instrumentation & Control Companies:

These types of organizations provide a channel for engineering to make their future bright as they hire instrumentation engineers for work in designing and maintaining the instrumentation system used for monitoring and controlling operations in an industrial process.

Automotive and Aerospace Companies:

The carmakers and top-tier suppliers of vehicles find these engineers valuable for having imbibed the science of embedded systems, automotive electronics, and mechatronic subassemblies.

Electronics and Embedded System Firms:

These companies tend to recruit anyone who possesses skills regarding sensor integration, microcontroller, real-time systems, and PCB design.

Oil, Gas, and Chemical Industries:

Such industries as process industries require instrumentation engineers to carry out their operations safely and efficiently on automation, control, and measurement systems.

Renewable Energy and Smart Grid Companies:

These companies recruit talent to fill their positions such as controlling solar/wind power systems, battery management systems, and intelligent energy metering.